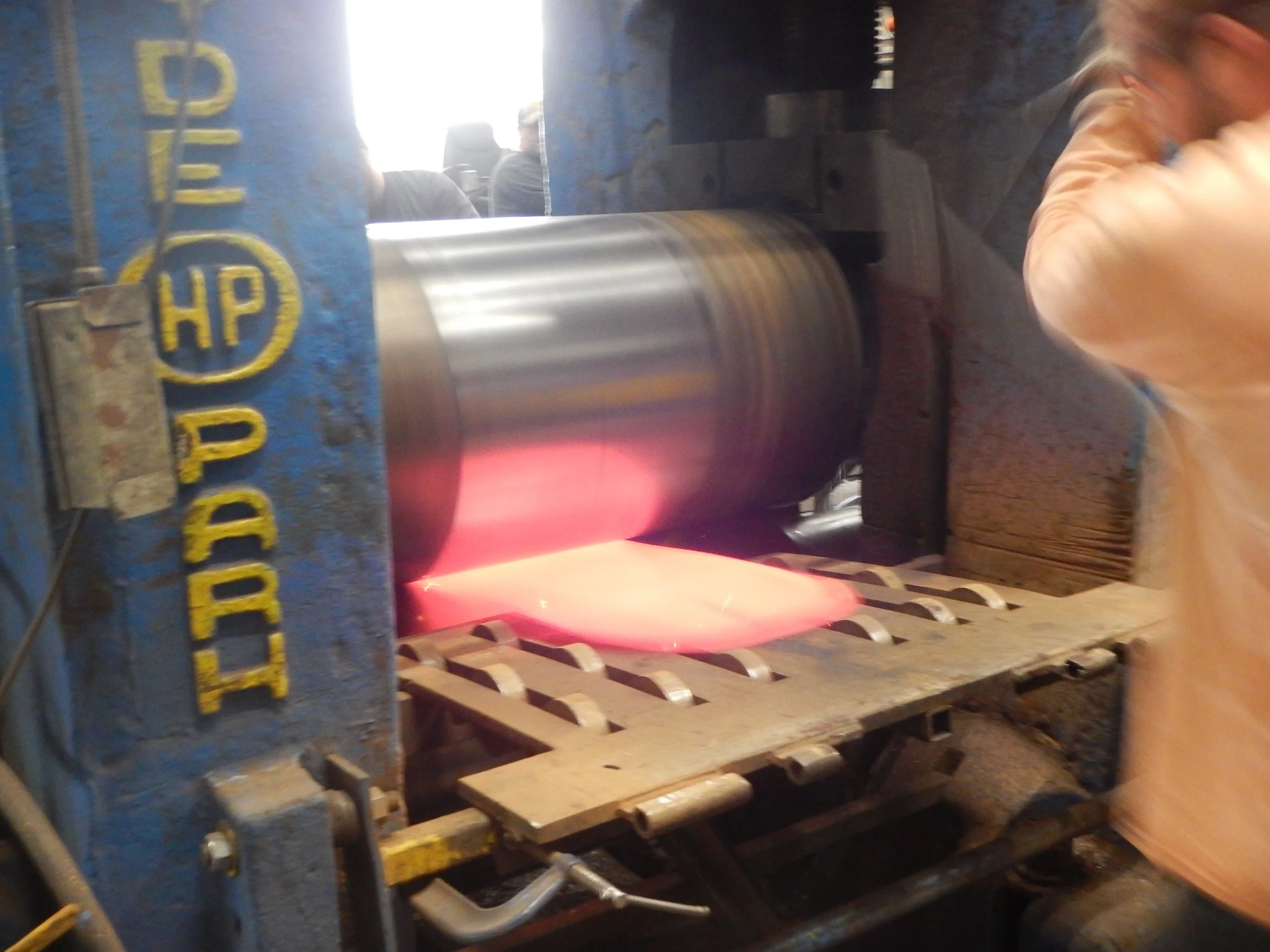

Over time, and through numerous iterations and utilizing a similar grade of construction steel similar to that of the WTC steel, Dekelbaum created the unique design/formula for the WTC Damascus. Prototypes were built and tested, also out of chemically identical steel, while the actual WTC steel remained in The Specialists secure vault. Once a viable design was finalized, with the necessary specifications for the WTC steel, Glen personally transported the WTC steel to Niagara Specialty Rolling Mill in Niagara New York. There it was cut and placed in an oven for 20 hours until it reached a temperature of 2000 degrees. It was then rolled out from 3” thick to 1/8” thick in accordance with Dekelbaun’s Damascus formula. After the rolling, there was initially a single piece but, because it was too large to transport, that large piece was cut in two.

Glen and Dekelbaum received the rolled WTC steel directly from and at the Niagara Specialty Rolling Mill, signed it with a sharpie, and loaded it onto Dekelbaum’s truck. Dekelbaum then personally drove the steel to his shop in Hanover PA where it remained in secure location until 2/5/2020

After several months during which the 2 large pieces of rolled and cut WTC steel were kept in a secure storage area at Dekelbaum’s shop, he personally transported the signed steel to a shearing mill in Hanover PA Dekelbaum remained at the mill as the WTC steel was sheared into two batches of differently shaped pieces that would be necessary to create the slides and frames of the commemorative guns. Because the guns are built in lots of 8, there were 54 pieces in the shape necessary for the frames, and an equal number cut to the shape necessary to make the pistols’ slides. Dekelbaum personally loaded all the pieces of sheared WTC steel into his truck and returned it to his shop where it was, and continues to be, maintained in a secure area.These pieces of WTC steel would, after Dekelbaum’s smithing, be turned into billets of Damascus steel.